NEWSLETTER

CLNA NEWS – August, 2013

Editor – Kelly Bass

Quarterly Review

The summer of 2013 has been a time of change for traditional CLNA traffic patterns. We have said goodbye to Hi-Cone in Zebulon, which moved its plant to Mexico, to the Southern States mill in Farmville, which is closing, and to Ready Mix in Greenville, which has resourced its materials. However, we have added new traffic to and from the Perdue facility in Belhaven, Coastal Carolina Cotton Gin in Terra Ceia, Mark & Sons and Quality Mats in Plymouth, Eastern Grain in Washington, TTE in Middlesex, and from the auto shredder at RMR in Rocky Mount. Work should begin in August on a new siding for Pencco in Middlesex, while the pellet plant in Sims should begin construction by the end of the summer. This shows the ever-changing nature of our business.

One constant, however, is the need for track maintenance. We are continuing with several projects, including rail change out on the Nash County line. We have been awarded two NCDOT matching grants, which will primarily be used for ties on the Belhaven Branch and the Plymouth-Raleigh main line. Our track department is doing a great job of addressing our daily requirements. Another constant is the need for quality locomotives. Our mechanical department has greatly improved the reliability of our power. In addition, we have just acquired an SW1400 that had been used at PCS in Lee Creek. This unit will be moved to Rocky Mount within the next few weeks.

At its annual shortline meeting in June, NS gave CLNA its platinum award for new traffic development last year. In addition, CLNA was named shortline of the quarter and featured in the NS publication iNShort.

Our annual Family Day at the lake drew about 60 people in spite of spotty weather. John Odham and Duane Willis were crowned cornhole champions, while Thomas Leonard and his daughter won the golf tournament.

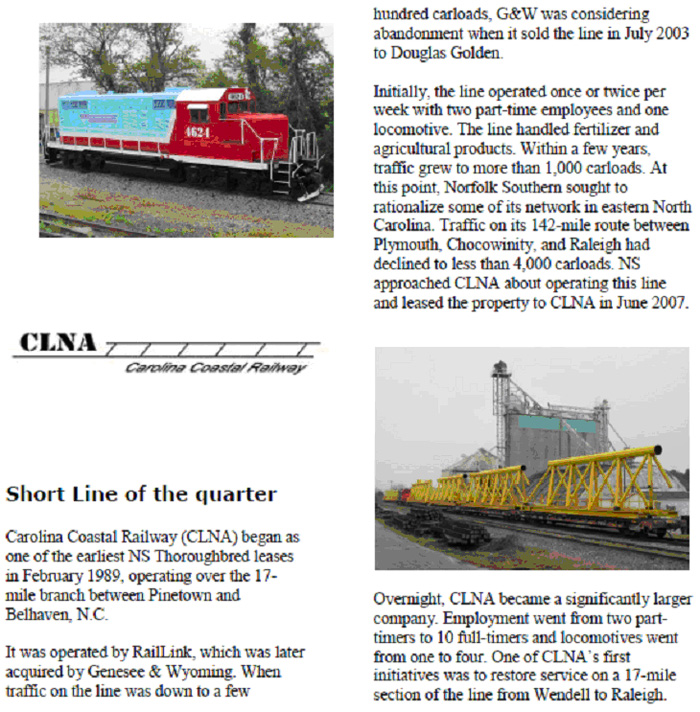

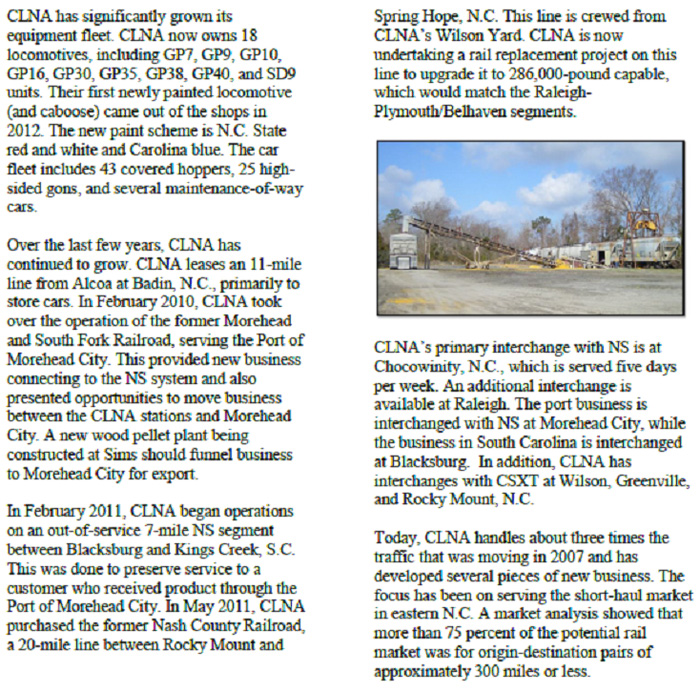

Below is the write up featured in the iNShort newsletter about Carolina Coastal Railway

continued below

continued below

continued below

Meet Our Customer

Ready Mixed Concrete Company, Rocky Mount

I stopped in to visit our customer in Rocky Mount, Ready Mixed Concrete, and talked with Plant Manager David Byrd. Mr. Byrd told me that they had been a little slow for the first part of the summer because of all the rain that we have been getting, but things were picking up and they had some big contracts to fill as soon as the weather cooperated. The day I was there, he was busy loading trucks and sending them out as fast as they would come back in. He actually had a couple drivers from other plants helping with the work. Mr. Byrd explained that they will share drivers and trucks with other Ready Mix facilities when one gets busy and if they are able to come. On this particular day, he had drivers using a couple spare trucks that were already on location. If there are no trucks on the yard, they will bring their own trucks as long as it isn’t crossing state lines due to different state restrictions. Ready Mixed Concrete Company is into manufacturing concrete for commercial and residential uses. They take rock, sand and cement and mix them electronically making different formulated concretes according to the job it is being used for. The computer makes measurements consistently each time so even on a job that takes several truck loads, the mixture is the same with each pour. Mr. Byrd explained concrete is measured by cubic yards. A cubic yard is measured by the weight of the material. To keep a consistent final product, scales are calibrated every 6 months or so. Trucks can max out at eleven to twelve cubic yards, but with the electronic controlled mixing can get exactly what is ordered without much waste. They have rock and sand delivered on site from local areas and the cement comes in by rail from different suppliers. He added that they use different cement suppliers so they will always have an open door to receive product if for some reason one plant can’t provide an order when needed. The cement can be delivered by truck in a pinch, but a rail car can hold 4 tanker trucks so it is a lot more feasible to get it in by rail. Plus, a railcar can be unloaded as needed where a truck would need to be unloaded upon arrival. When business is going good, Mr. Byrd said he can do about two or three rail cars of cement a week. The Rocky Mount site has about 10 employees working Monday through Friday with an occasional Saturday for special large orders.

I asked Mr. Byrd about CLNA’s service and he told me “service was good and when cars arrive in the Rocky Mount yard I usually get them the next day”. Carolina Coastal interchanges with CSXT in Rocky Mount via the Nash County line. He also added that it was easy to get a hold of someone and if he had a question, someone would find out an answer for him. As lunch time was approaching and I was wrapping up my visit, Mr. Byrd told me that they had the contract to supply concrete for the remodeling job on the local Krispy Kreme. Which, I’m not sure if you can call it a remodeling, or rebuilding since the only thing left of the old store at the moment was the sign out front. Either way you want to say it, I was on my way to find a donut when I left.

Meet Our Employees

Nick Rowland, Track Foreman

Nick started with us in April of 2012 working in the track department and has moved up to Track Foreman. He comes to us from the western part of Tennessee with 5 years experience in track and railroading. Nick said he looked to Carolina Coastal for work to be closer to the beach. Most of Nick’s family still resides in Tennessee and he is making plans during vacation to visit home. In his spare time, Nick likes to tinker around the house playing video games, grilling out with friends, fishing and target practicing. He told me he would get down to the beach more often but he is usually helping someone work on a project. Lately, he has been helping to build a small boat. He told me it wasn’t anything fancy, but it is interesting to watch it come together and can’t wait to see if it will actually float. Nick said he usually doesn’t have big plans on the weekends, so when a friend calls and asks if he can help them with something, it’s not a problem to go. He also told me he likes to visit different restaurants and is really looking forward to trying some down at the beach to get some fresh seafood.

Nick said his position as Track Foreman is a work in progress and takes it one day at a time. He has a lot more to learn and with that, comes a lot more responsibilities. He told me it was long hours, but enjoys the guys he works with because they are able to joke around and keep everything upbeat. I met Nick and his crew after a long, hot day of putting in ties and they were still laughing and joking around the whole time while we talked. He added that he felt a sense of accomplishment when they got a job done but knew a new day would bring a new task to work on. Nick likes working with the track equipment and says one day he will be able to learn to run them all. Nick also told me he has helped do work on some of the bridges that the CLNA has been working on this past year. This experience has taught him more about bridges and the structures themselves. I asked Nick about the railroad itself and he said he hopes business grows. When business grows, he is hoping to get a couple more track guys hired on and get some more track equipment to work with.