NEWSLETTER

CLNA NEWS – August, 2012

Editor – Kelly Bass

Quarterly Review

During the spring and early summer, traffic on the CLNA was slow, although our storage traffic significantly increased. Still, progress continued to be made toward some long-term growth. Work continued on a new auto shredder at Rocky Mount and construction began on a facility for Pencco at Middlesex. The wood pellet project at Sims appears to be moving ahead, although slowly. We are in active discussions for considerable new traffic moves through Morehead City, some of which may possibly originate on the CLNA main line.

The first locomotive painted in our new color scheme, #4624, has been completed. Hopefully, at least one more unit will be done this year. Considerable work has been completed toward the replacement of 85# rail on the Nash County line. About 1.5-2.0 miles will be done this year. In addition, a new 25-car siding is being added in Rocky Mount, which will increase our storage and interchange capabilities.

We had nearly 50 people at our annual Family Day at the Lake, including 15 golfers. Golf, corn hole, and horseshoes were enjoyed by all. A few days earlier, the Morehead City crew and families joined several customers for an outing at the Morehead Marlins baseball game.

At the NS shortline meetings in mid-July, CLNA won several awards. First, CLNA won a Piedmont Division General Manager’s award for excellence in interchange and operational cooperation. CLNA also won a marketing award from the NS Metal’s and Construction group for new steel business at Morehead City and stone business on the main line. As part of the NS 250-squared marketing initiative, CLNA won a platinum award for generating more than 3,000 cars of new business (the second most of any NS shortline). Finally, each year NS selects a “shortline of the year” award from among its more than 250 connecting roads. CLNA received the bronze award for shortline of the year in 2012.

Left - Doug Golden, Virgil Holman with NS Reps. receiving Platinum Award for New Business

Right - Doug Golden and NS Reps. receiving Metals and Construction Marketing Award

Left - Doug Golden and Virgil Holman receiving the General Managers Operating Award

Right - Doug Golden, Virgil Holman and NS Reps. receiving the Bronze Award for Shortline of the Year

5 YEAR ANNIVERSARY!!

Newly painted CLNA 4624

This past June, Carolina Coastal Railway celebrated five years of its expansion from the Belhaven Branch line to include the Plymouth to Raleigh line. When CLNA started with the Branch line, a promise of service was made to each customer. We will run on certain days no matter if it is one car or 20 cars. The first 6 months there were less than 10 cars moved. The promise stood and slowly customers began to come back to the line and today the line has as much traffic as it did 30 years ago when business was booming. When the little CLNA became the bigger CLNA, that promise carried over to our new customers. We promise service whether it is one car or 50 cars. Every year, car loads have increased on the line and we still have encouraging talks with future business coming to the line. What can happen in five years? A new born infant can be starting school, a person can get a college degree, and a new home can go from being a dream to built and lived in. A lot of life altering things can happen and be done in five years. When we first started the mainline operation, we had two engines and two crews. Today we have six regular crews and can make an additional crew or two if needed to go along with almost 20 locomotives. We’ve acquired the Nash County line originating in Rocky Mount and the Port at Morehead City. Both lines add to the CLNA mainline customer base. We also switch the Kings Creek to Blacksburg line helping to preserve a customer that had a lot of product coming through the Morehead City Port.

We’ve purchased on average 20,000 ties every year to place on the lines and have replaced over two miles of track on the mainline with more slated to be done this fall. That doesn’t include single sticks here and there to repair spots. We’ve also put back into service numerous sidings and/or customer tracks to accommodate potential customers and increased business. We’ve done extensive work on bridges including superstructure or decking. The swing span in Washington has been automated with push button controls to make operation more dependable and reliable. Work is also slated this fall to be done on a few more bridges. There have also been numerous new highway crossing signals installed with an additional number being upgraded from existing signals.

Carolina Coastal also participates with Operation Life Saver and local authorities in doing rail blitz to inform the public of railroad crossings and safety. Once or twice a year, employees team up with these authorities to make the public more aware. Recently CLNA teamed up with the NC State Patrol and other town police officers to give rides on an engine to show what it was like for a train to go through a highway crossing so they could better understand a scene if there was ever an accident.

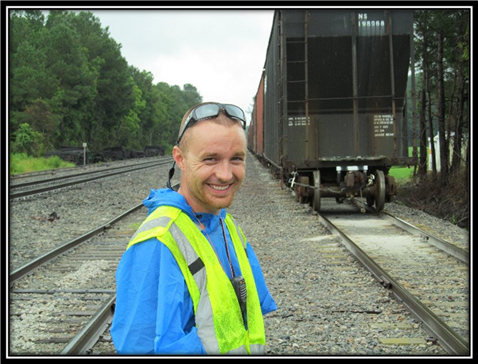

Scott Rogers with local Police Officers after giving rides on the locomotive

We also want to celebrate five years of service for five of our employees who have been here since day one. These employees worked long hours and hard days in the beginning to help make CLNA what it has grown and become today. These employees were learning new things from trial and error, working to improve conditions, fighting to get more help and pushing to get more power. Many people don’t understand how we paved the way to make things better. There were about 8-10 employees when we started. Today we have about 30-40. Our locomotive numbers have vastly grown. Crews were working 10-12 hours daily to get the work done. Now crews are averaging 8-9 with an occasional longer day tossed in. Interchanging with NS was a stand still in Chocowinity. We worked and worked to find a solution to get crews in and out in a timelier manner. Today crews are able to go and interchange with very little, if any, delay. Our goals are to continue to work on improving the railroad, our customers, and conditions for our present employees and future employees. Five years from now, our goals will still be focused on improvement, growing, and doing better.

left to right - Doug Golden, Scott Rogers, Stacey Hobson, Virgil Holman, Paul Thornhill, and Kelly Bass…

All 5 Year Employees, Congratulations!

Meet Our Customer

ITW Hi-Cone

Hi-Cone is one of our customers located in Zebulon NC. They receive railcar loads of small plastic pellets to make plastic ring carriers. I met with Plant Manager, Philip Robertson, and he explained to me how they use the pellets to make sheets of plastic where their final product comes out as one of those plastic rings found on your six packs of sodas, Coke, Pepsi, replenishment drinks like Gatorade, and some beer products. Hi-Cone has been producing these rings since the early 60’s and ship all over the United States with two other plants located in Chicago and Southern Illinois. The Zebulon Plant mainly distributes up and down the east coast but do send their product where ever needed in the system. Mr. Robertson also told me they ship a metal container of rings over seas about every month or so. Hi-Cone is part of ITW, Illinois Tool Works Company, and was one of the first 3 started by ITW. Today, ITW has close to a thousand small manufacturing businesses under their wings spread all over. Business is slow for Hi-Cone right now. An average year consist of one billion rings made, this year is on track for around eight hundred and fifty million. Mr. Robertson tells me the economy affects them just like anyone else. The only difference being when it does get a little better, they can see it more immediate than other companies. That also has the down fall of when it gets worse; they feel it quicker than others also. He tells me the past couple years the plant has shut down around the week of Thanksgiving and the week of Christmas because of business being slow. To me, that sounds fantastic, but then reality is that unless they have some vacation time saved, they don’t get paid for the time off except for regular holiday pay. The plant has about 45 employees covering 3 shifts.

![]()

From a train crewman’s point of view, Hi-Cone is a great place to switch. They pull product from the bottom railcar up. This means every empty they have will be on the bottom. You bring in the new loads, couple up to the cars sitting there, pull everything out, set over the empties off the bottom and shove back in to spot. When Carolina Coastal first started switching Hi-Cone they had numerous cars sitting at the plant and in the yard in Wilson. This was in part of not knowing when they would actually receive a switch and they needed to be sure they would have plenty of cars to get all the loads they could. CLNA’s commitment to service has allowed HI-Cone to cut down their online inventory. Loads come in now and get spotted as empties are released keeping a steady flow of cars moving. Less cars sitting around waiting to go to the plant means less overhead cost for the plant. Over the years, plastic rings have gotten a bad rap environmental wise. Hi-Cone is committed to adjusting to changes of rules and regulations. One of these changes from research and development is that the rings will breakdown and loose 75% of its strength within days in direct sunlight and be brittle and fall apart within weeks. I’m sure these numbers will continue to improve with continued development over time. Hi-Cone is also committed to recycling programs nationwide where plastic rings are sent in and reused in the manufacturing process. Mr. Robertson told me that any product can cause environmental problems if disposed of improperly. Their goal is to educate proper disposal, hopefully to a recycling center, while still keeping the product as safe for the environment as possible. Mr. Robertson said that Carolina Coastal did a good job and communicated very well with them on when they were to receive a switch. They don’t receive a switch daily, so it helps when someone from the railroad calls and lets them know there is a load on the way out to them

Meet Our Employees

Josh Boseman

Josh comes to us with 5 years of railroading experience from CSXT. He has been with us for about a year as a conductor and is currently working on getting his Engineer’s license. He applied for a railroad job after family members with careers in railroading told him it was a good job to get into. Josh has been married to his wife, Brittany, for two and a half years. They have a 10 month old, Amelia, and weekend custody of Kaylie, who is 5. Brittany just finished school to become a special-ed teacher and is excited to start work this fall with the new school year. I asked Josh what some of his hobbies were and he told me he use to hunt and fish. Then he added with a smile, now I watch Mickey Mouse Clubhouse on the weekends with my girls. They also like going to local parks in Rocky Mount and the Children’s Museum when the weather is nice. Josh and Brittany take the girls to visit friends and family when possible because Josh tells me family is most important to him. They also attend church and are as active as they can be, but is hard to do with a small child. With Brittany finished with school and starting a new job, they plan to buy a new home in the next couple years once they get caught up on some finances.

Josh, being a family guy, says he loves the family atmosphere with the guys he works with. Most of them have a family of their own and have some of the same values he has. His goal is to get the work done safely and go home to his wife and kids. He likes the Family Day picnic at the lake we have each year. It gives employees and their families’ opportunity to meet each other and be more in touch, more personal, with the company. He also brought up the Christmas party and how the company shows some appreciation to all employees. Not many companies make such an effort to show how valuable each person is no matter what their job duties are. Josh is excited to get qualified as an engineer and is ready to see how far he can go with the CLNA.